Where Can You Use Temperature Loggers?

Temperature loggers have obvious uses in shipping, restaurants, and the medical and healthcare industry. However, their usefulness extends quite a bit farther than just that. Most industries have a sector of their business that requires some temperature monitoring to a certain extent.

Even IT industries need to control temperatures around sensitive equipment. Likewise, bakers, cosmetic companies, and even compounding pharmacies need to keep ingredients within a certain temperature range.

Where else can you use temperature loggers? Read on to find out!

The IT Industry

Computers, electronics, servers, and most types of technology produce some amount of heat. When they get into the same room together, even a little heat adds up. If say, one server can raise the room a single degree, that’s not a big problem. Of course, that’s also assuming you have proper ventilation. However, a lot of servers stay in a backroom that doesn’t get as much airflow as it should. Not only that, there’s rarely a whole room devoted to a single server.

Computers, electronics, servers, and most types of technology produce some amount of heat. When they get into the same room together, even a little heat adds up. If say, one server can raise the room a single degree, that’s not a big problem. Of course, that’s also assuming you have proper ventilation. However, a lot of servers stay in a backroom that doesn’t get as much airflow as it should. Not only that, there’s rarely a whole room devoted to a single server.

In most cases, the IT equipment room is filled with as much tech as it can hold. That means several servers, back up gear, and much more. If one server raises the room temperature by a single degree, with good ventilation, then several makes the room much warmer. Say there are five to ten servers. That’s easily a ten degree difference, without considering any other equipment.

Unfortunately, this rise in temperature can cause equipment to overheat, and ultimately crash. Not only that, but there’s a threshold where that equipment (and data it holds) can’t be recovered.

A temperature sensor can alert you to a potential problem before you lose valuable equipment and data.

Alcohol and Beverage Industry

Everyone likes a refreshing cold one, right? That’s one reason the alcohol and beverage industry is one of the biggest examples of temperature controlled business. This industry has a lot of influence on overall lifestyle habits, and our social activities. Of course, there’s a big difference between a cool, refreshing beer, and an unpalatable (to put it kindly) bottle of brew.

Everyone likes a refreshing cold one, right? That’s one reason the alcohol and beverage industry is one of the biggest examples of temperature controlled business. This industry has a lot of influence on overall lifestyle habits, and our social activities. Of course, there’s a big difference between a cool, refreshing beer, and an unpalatable (to put it kindly) bottle of brew.

For these companies to maintain the integrity of their products, and well as the taste, they need strict temperature control. This temperature control doesn’t just start at the brewing and manufacturing stage. It extends into distribution, and continues all the way to the end consumer. Without proper temperature control throughout the entire process, the manufacturer can’t ensure the same quality, flavor, or standard.

A lack of temperature control can do more than hurt a single case of brew. It can also ultimately damage a brewery’s reputation for quality.

The Cosmetic Industry

A lot of cosmetics come with instructions to store them within a certain temperature range. However, these are meant for the consumer, and they’re typically within a pretty broad range. The real importance of monitoring temperatures comes in at the actual manufacturing, and shipping stages.

A lot of cosmetics come with instructions to store them within a certain temperature range. However, these are meant for the consumer, and they’re typically within a pretty broad range. The real importance of monitoring temperatures comes in at the actual manufacturing, and shipping stages.

In extreme cases, the temperature can affect the color or finish of a cosmetic product. However, the bigger issue is often with consistency and integrity. It’s no mystery that makeup can melt when it gets too hot. That’s one issue, but another is with ingredients that aren’t stored properly can create an off putting texture in the end product.

Another important segment of the cosmetic industry that relies on temperature control is one you won’t think of right away. What is it? Wax strips. When it comes to these, and especially those made for professionals, the right temperature is key for a quality product. If the strips reach temperatures that are too high, or even too low, the consistency of the coating on the strips won’t stay. That means the consumer is left with an expensive, and often unusable product.

How Can You Use Temperature Loggers?

The best way to use temperature loggers is by placing them in any area where you need a strict temperature range in place. Think about where you keep your most valuable (and temperature sensitive) stock. That’s where you need a temperature logger.

It does more than just read out ambient conditions. You can use a thermometer for that. However, if you want to use a thermometer, you’ll need someone to check it at regular intervals. Then, you’ll need to hope there’s no human error, and that everything gets logged properly.

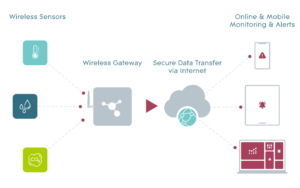

Simply place your temperature monitor in a central location in your climate controlled room. Then, connect it to the gateway, install your application, and let it get to work. You’ll have access to records of the temperature readings at any time of day. Not only that, you can also look at a log of the monitor’s reading history. Many temperature loggers also give you the option to receive an alert. These alerts basically tell you whenever the logger reads temperatures outside of the optimal range you set.